OUR STATE-OF-THE-ART ROUGH DIAMOND CUTTING AND POLISHING facility is performed by highly qualified cutters and polishers with whom the art of diamond cutting and polishing is elevated to incomparable levels of precision and perfection.

We are equipped with the best diamond processing technology for the production of all diamond cuts which, in turn, allows us to offer you customized cuts either from rough diamond or from a polished diamond.

Our craftsmen have experience of over 25 years.We manufacture all sizes and all shapes. Our expert craftsmen will also craft as per your SPECIFICATIONS.

THE STUDY AND THE CUTTING OF A ROUGH DIAMOND is the most important factor in a diamond's brilliance, and it is critical to its beauty. The process of maximizing the value of a finished diamond from a rough diamond into a polished gemstone is an art and science. The unique character of this wonder of nature requires artistic skills. Knowledge of the rough diamond, assessment of their potential, and creativity are key words for us. Our diamond cutting team takes pride in manufacturing the highest quality products available today on the market.

| Diamond cutting involves 5 basic steps: Marking, cleaving, sawing, bruiting/girdling, faceting.

Marking: Marking is done after examining each rough diamond to decide how it should be cut to yield the greatest value. Taking these factors into account, the planner decides how the diamond should be cut and marks it to indicate where the stone should be cleaved or sawed. We also evaluate the highest profit within different shape to get the best quality diamond to the customer at the most affordable price.

Cleaving: Cleaving is the separation of a piece of diamond rough into separate pieces, to be finished as separate gems. Diamonds can be cleaved or sawn. The expert diamond cutter decides which option to choose. Cleaving the diamond only takes a few seconds. It involves a chisel and hammer and it must be done with the grain of the diamond otherwise the stone will break in a way that will ruin it.

Sawing: Most diamonds are sawn. The sawing process involves a special blade coated with diamond dust which spins at high speed to gradually cut through the stone. Once this part has been done, the diamond is sent back for checking and then passed to the next phase called bruting.

|

EACH ROUGH DIAMOND REQUIRES an individual approach to reveal its hidden beauty. Every day, this renewed challenge is an increasing source of fascination to us. We have mastered the art of cutting, WE ALSO LOOK FOR THE HIGHEST RETURN WITHIN THE HIGHEST PROFIT OF THE STONE.

WE CAN EASILY CUT TRIPLE EXCELLENT DIAMONDS.

WE ALWAYS USE THE RIGHT DIRECTION TO CUT OUR DIAMONDS.

WE NEVER HEAT THE DIAMOND NOT TO CHANGE ITS ORIGINAL COLOR OR NOT TO UPSET THE STRESS INSIDE THE DIAMOND.

WE NEVER HEAT THE DIAMOND NOT TO CHANGE ITS ORIGINAL COLOR OR NOT TO UPSET THE STRESS INSIDE THE DIAMOND.

Our services also includes re-cutting and re-polishing damaged or chipped stones to improve cut, purity and proportion. This may result in marginal weight loss but at the same time the result is a pricier well cut diamond. We can help increase the value of your diamonds by improving the cut and possibly color of the diamond. We only work with GIA and AGSL to achieve excellent and ideal cuts as well as clarity and color improvements. | Bruting: Bruting is the process whereby two diamonds are set onto spinning axles turning in opposite directions, which are then set to grind against each other to shape each diamond into a round shape. This is the only way to actually form the shape of the diamond; by having it manipulated by a second diamond. This is also called girdling.

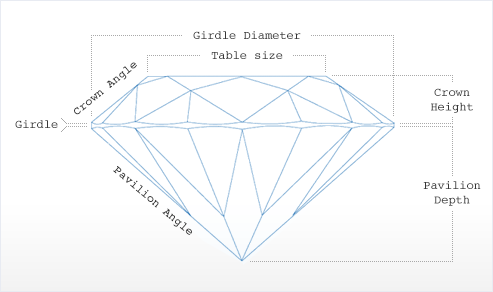

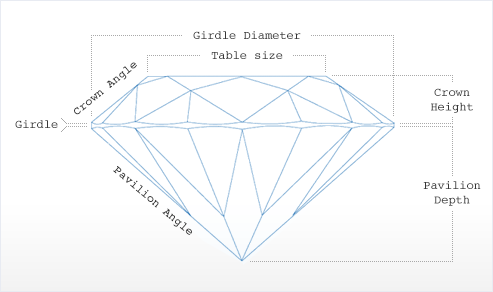

Faceting/polishing: Polishing is the name given to process whereby the facets are cut onto the diamond and final polishing is performed. In the initial blocking stage, the diamond cutter carves 18 facets into the diamond upon which all of the other facets will be built. Placing and polishing are done by setting the stone either in a lead dop or a mechanical clamp and holding it down on a revolving cast-iron lap (horizontal, circular disk) that has been charged with diamond dust. Great skill is necessary at every stage, but especially during faceting, because the angles of the facets must be exact in order to yield maximum brilliancy, and their sizes must be accurately regulated to preserve symmetry.

|